Care and maintenance of addiExpress knitting machines

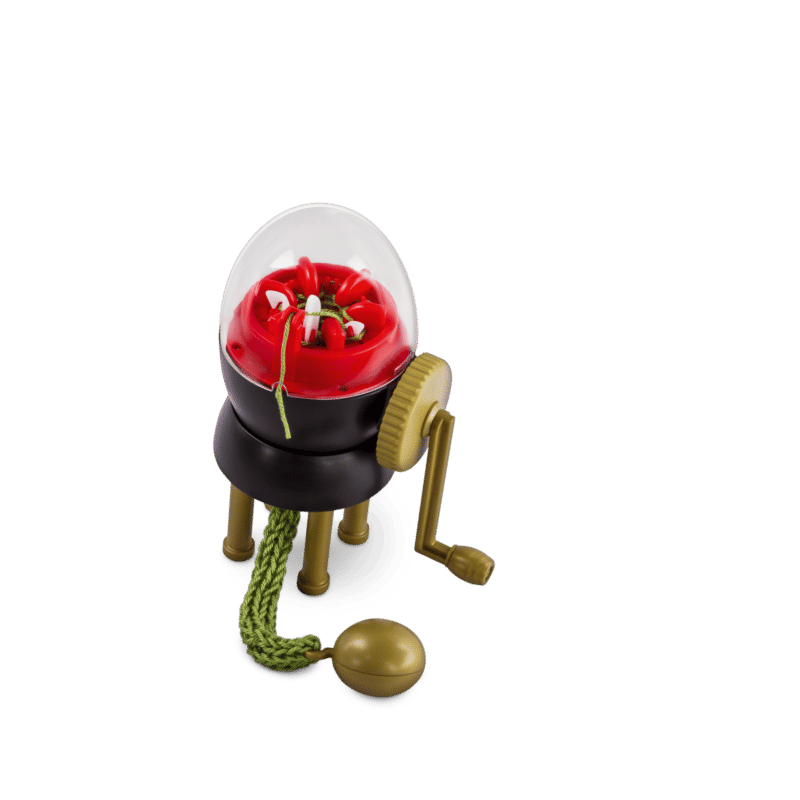

Care and maintenance of the addiExpress knitting machines is crucial to prolonging their life expectancies and ensuring optimal functionality.

How to clean addiExpress knitting machines

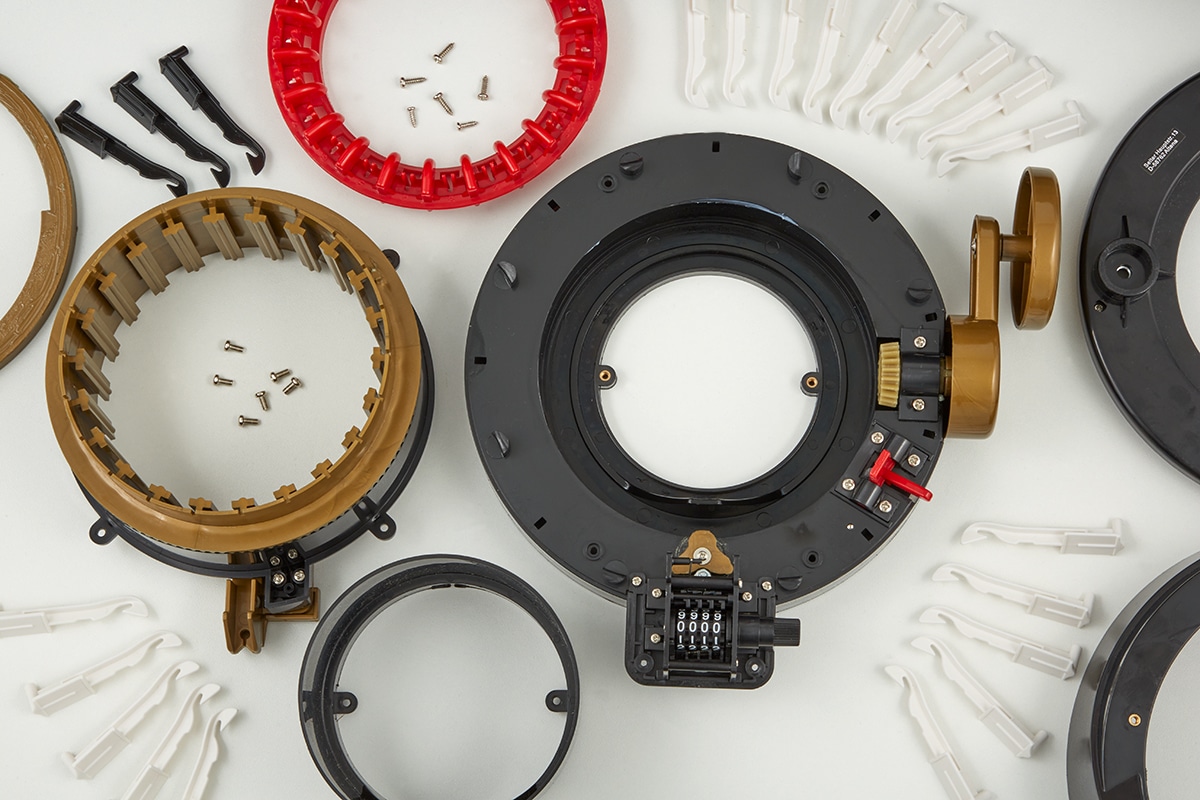

From time to time, for example, when the machine seems to run less smoothly, you should take it apart, brush it out carefully to remove dust and fluff, and clean it with a damp cloth.

Not sure if the knitting machine is working properly or if there is a fault? You will find the answer in our FAQs.

Tip: if stitches are being skipped, remove the work from the machine and turn it upside down. Use an empty spray bottle to blow air into the inside of the machine and remove any bits of yarn and fluff as they can impair the machine’s functionality.

Replacement of defective parts on addiExpress knitting machines

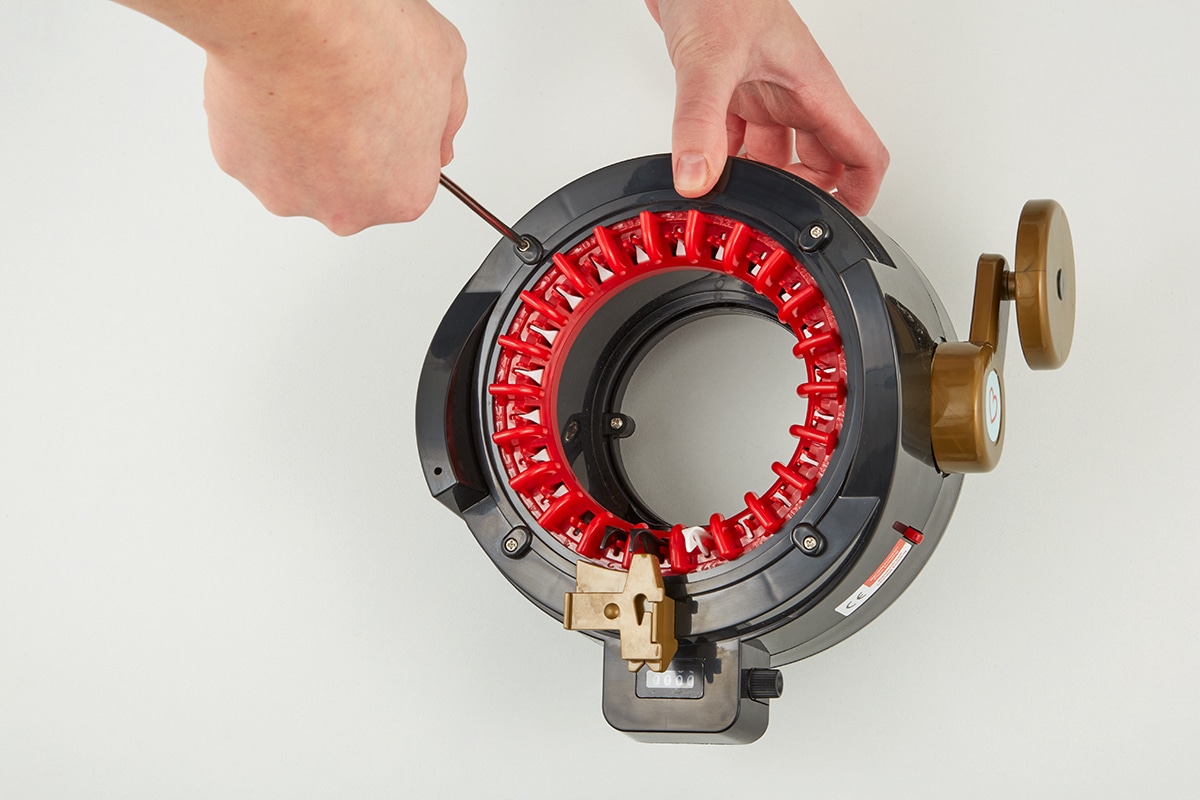

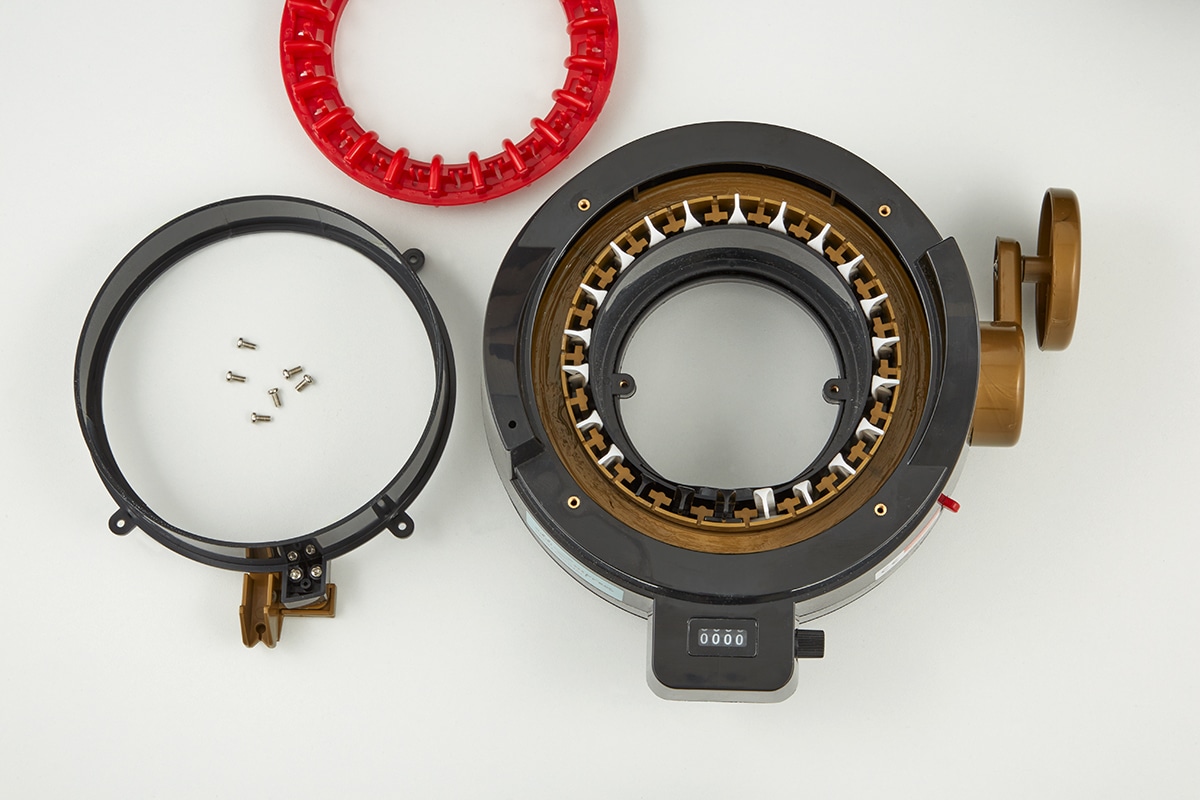

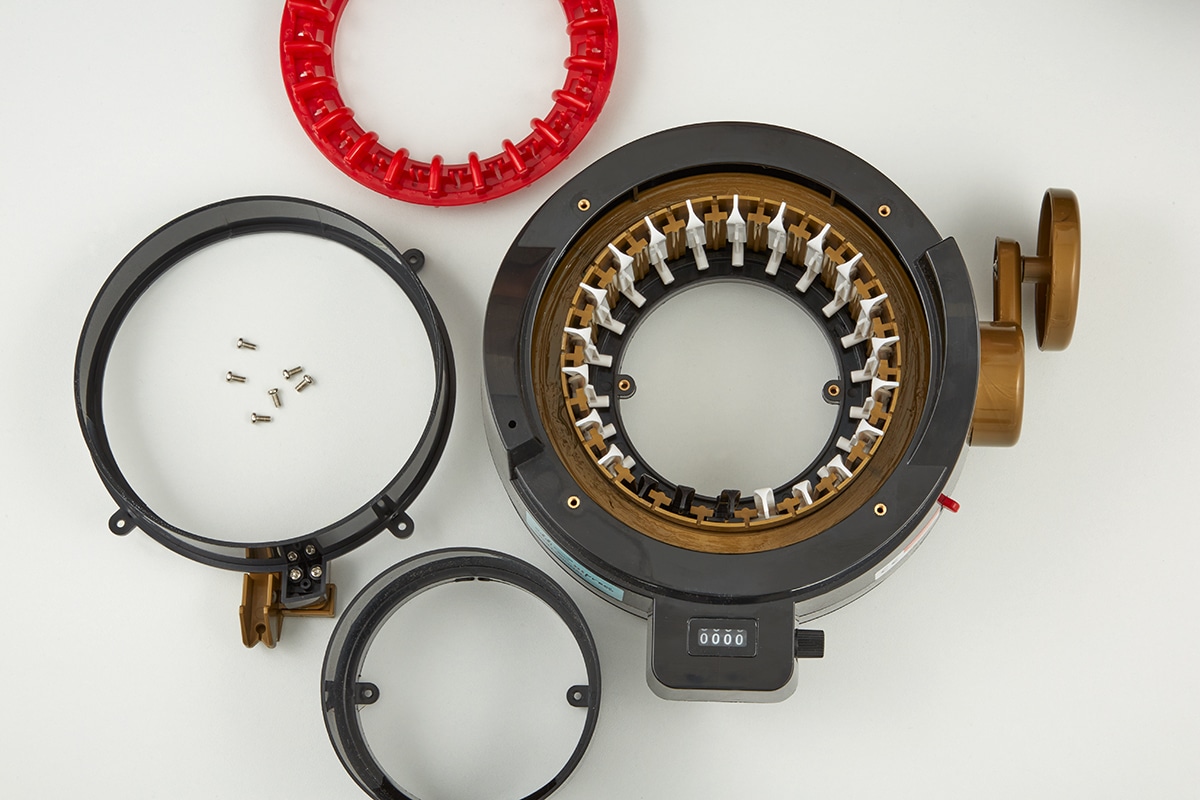

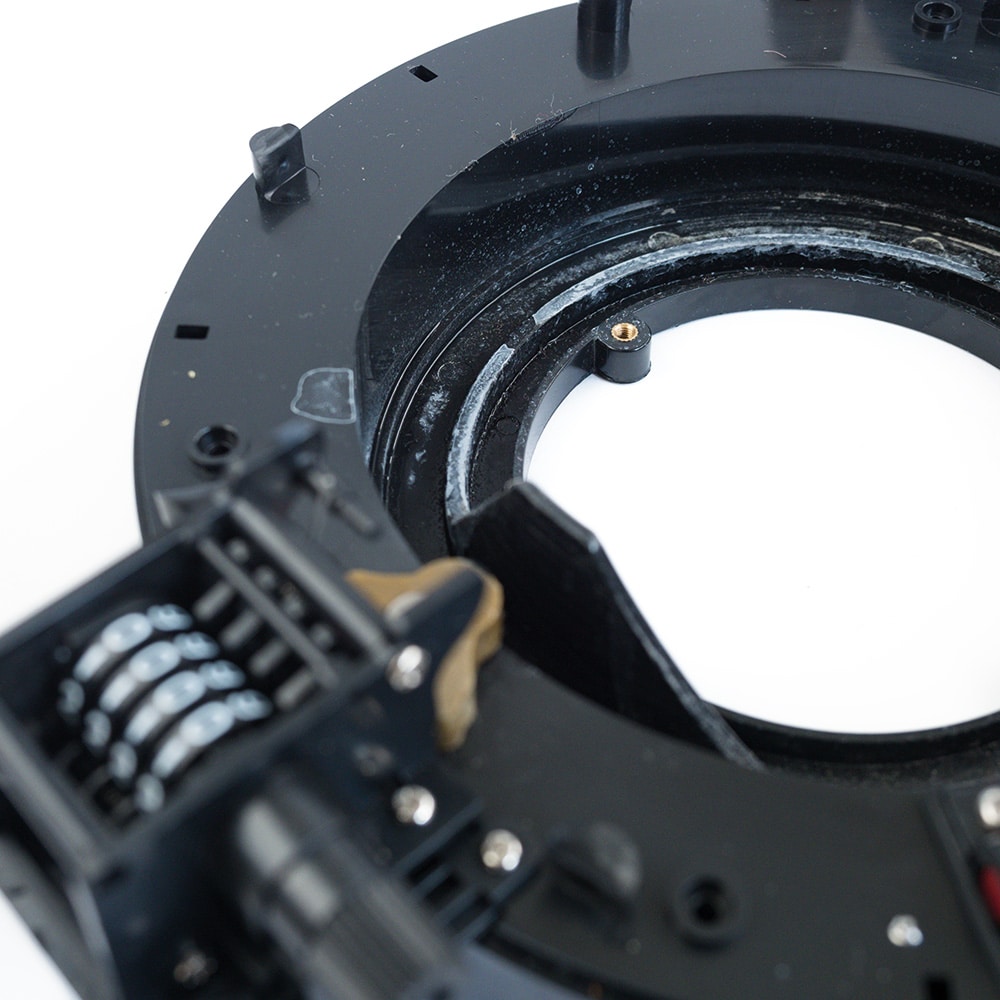

Disassemble up to the corresponding part (see picture descriptions) and then reassemble backwards.

Replacement of defective parts on addiExpress knitting machines

Disassemble up to the corresponding part (see picture descriptions) and then reassemble backwards.

Lubricate addiExpress knitting machine

Before you put the machine back together again, we recommend lubricating it. Apply dry lubricant to the sliding rail of the needle feet (photo 1). When the spray is dry, it will look like chalk marks on the sliding rail. This creates a lubricant film

After this treatment, the machine will run like… Well, like a well-oiled machine once again! Once you have put the entire machine back together again, you can spray dry lubricant into the needle slits (photo 2) when the needles pop up.

After this, you must leave the machine to dry for 12 hours! When the machine is fully dry, the needles will glide up and down with hardly any resistance.

Lubrication tip:

we recommend using a PTFE dry lubricant spray that is suitable for use on metal and plastic parts (please check when purchasing).

Lubricate addiExpress knitting machine

Before you put the machine back together again, we recommend lubricating it. Apply dry lubricant to the sliding rail of the needle feet (photo 1). When the spray is dry, it will look like chalk marks on the sliding rail. This creates a lubricant film

After this treatment, the machine will run like… Well, like a well-oiled machine once again! Once you have put the entire machine back together again, you can spray dry lubricant into the needle slits (photo 2) when the needles pop up.

After this, you must leave the machine to dry for 12 hours! When the machine is fully dry, the needles will glide up and down with hardly any resistance.

Lubrication tip:

we recommend using a PTFE dry lubricant spray that is suitable for use on metal and plastic parts (please check when purchasing).

Spare parts addiExpress

Individual spare parts for repairing addiExpress knitting machines can be found here.

You can see how to replace the parts step by step in the picture gallery above. In the playlist of our partner Skacel you will also find videos on how to replace the parts.