21 steps to the addiPremium circular knitting needle

How are addi knitting needles produced and how many steps does it take to get to the finished circular knitting needle? We always like to show this to our guests during factory tours and now also summarized here for you in this story.

During factory tours here in Altena, we always hear the surprised question: “You only produce here in Germany?” Yes – addi has been producing since 1829 and 93% in Germany – only 7% of the products are bought in.

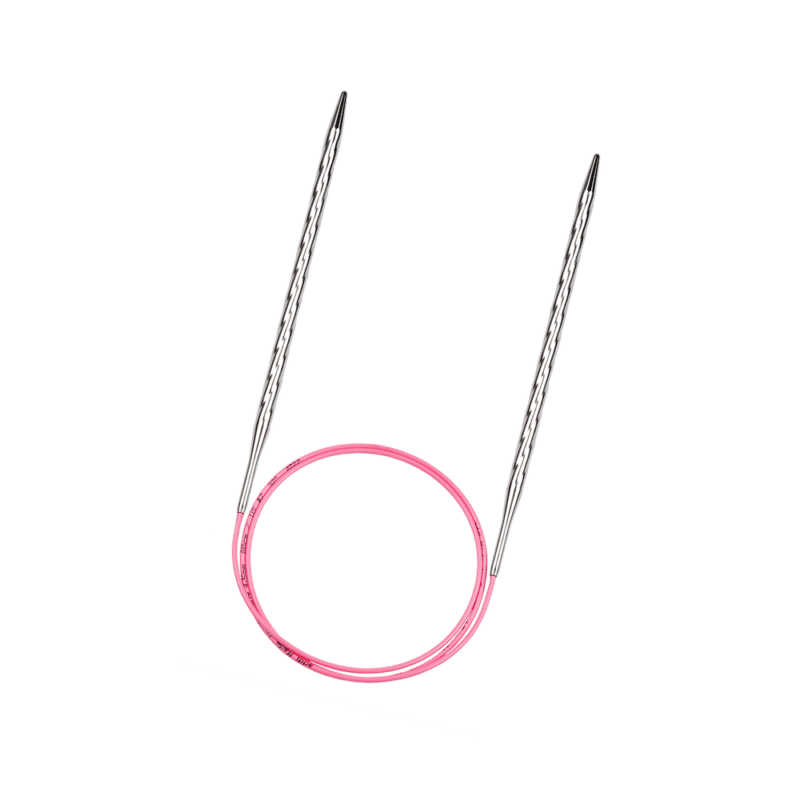

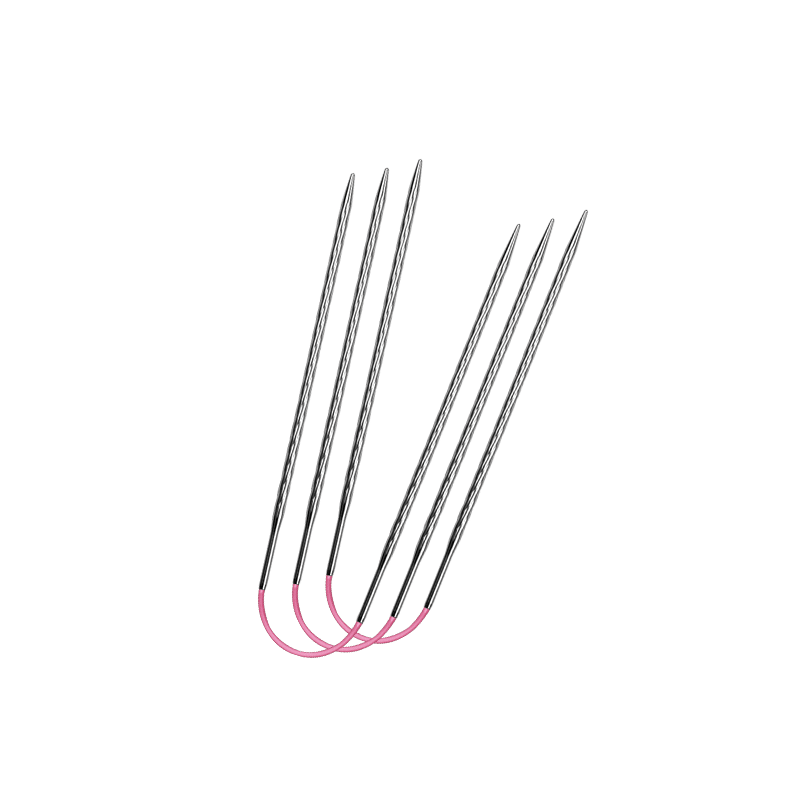

In the process, a finished circular knitting needle goes through countless steps – many of them handmade. We’ll show you what these steps are with our classic needle par excellence – the addiClassic circular knitting needle, which has been around in this form since the 1980s.

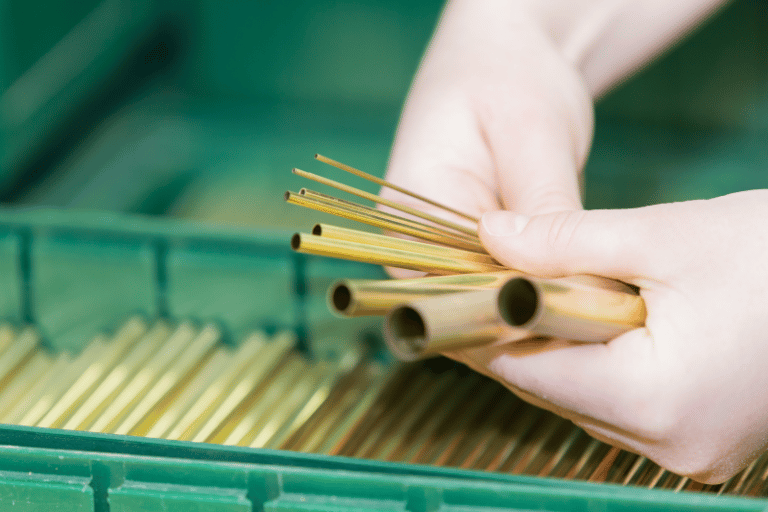

The raw material

Unser „Gold“ sind die Messingröhrchen – für jeden Nadeldurchmesser und jede Länge benötigen wir unterschiedliche Messingrohre, die anschließend zu Nadelspitzen geformt werden.

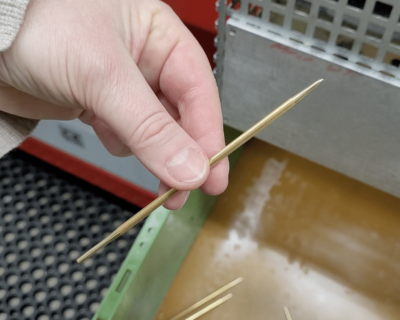

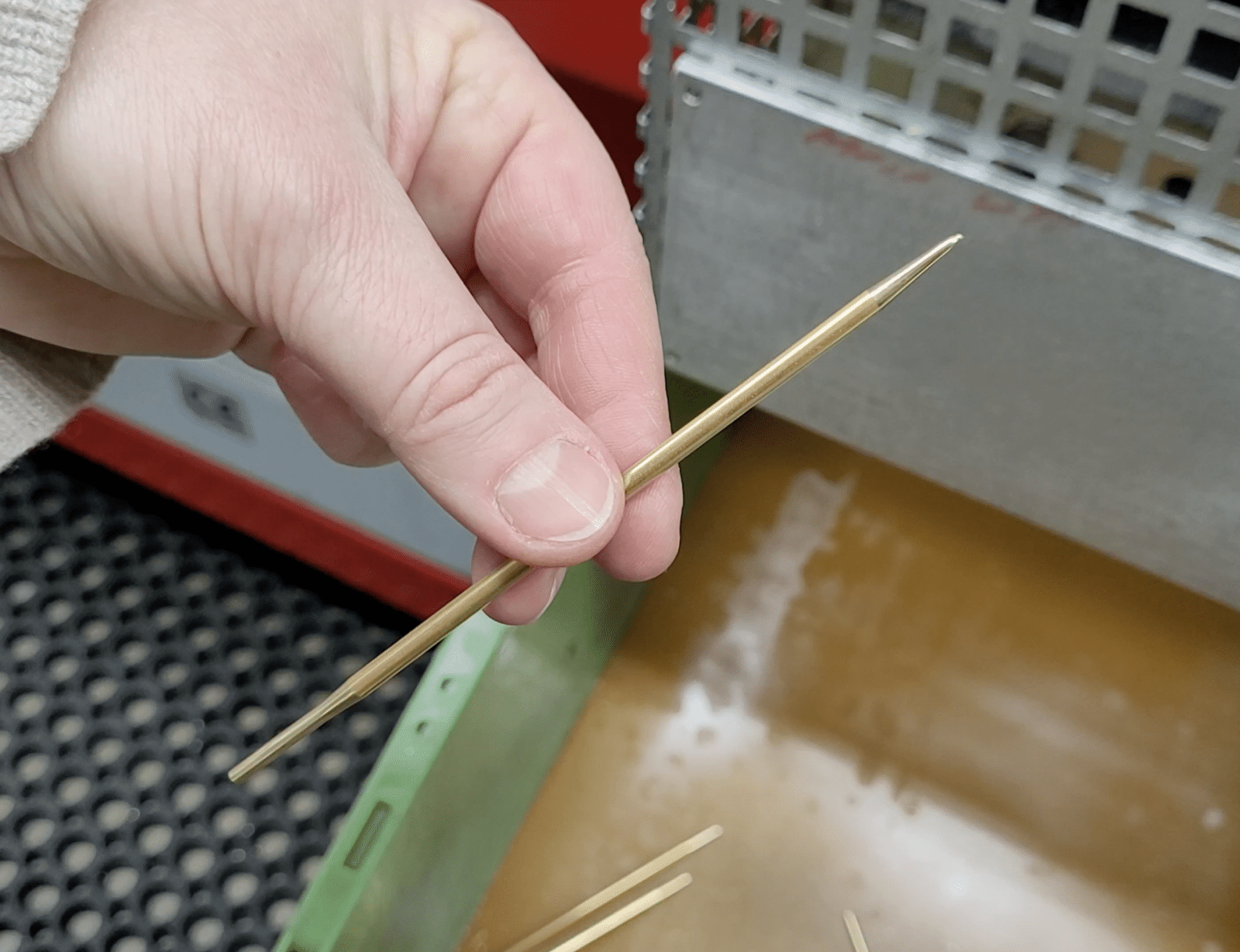

The raw material

Unser „Gold“ sind die Messingröhrchen – für jeden Nadeldurchmesser und jede Länge benötigen wir unterschiedliche Messingrohre, die anschließend zu Nadelspitzen geformt werden.

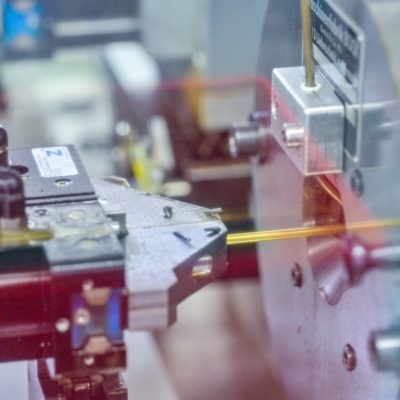

Sharpening the tube

The brass tube is sharpened to one side for the later Basic or Lace needle tips.

Sharpening the tube

The brass tube is sharpened to one side for the later Basic or Lace needle tips.

Reducing the pipe

Then the other side of the brass tube is reduced to create a transition to the later cord.

Reducing the pipe

Then the other side of the brass tube is reduced to create a transition to the later cord.

Washing the pipe

The brass tubes are covered with a layer of grease due to the machine processing. For the next step, this must be removed in a large washing drum.

Washing the pipe

The brass tubes are covered with a layer of grease due to the machine processing. For the next step, this must be removed in a large washing drum.

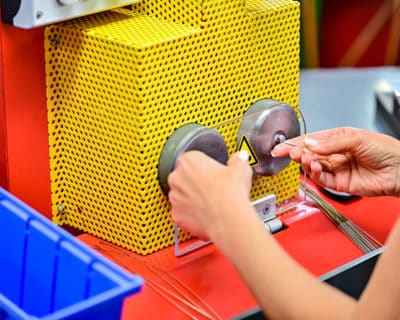

Polishing the tips

The thickening of the needle tip (caused by sharpening) must now be removed by polishing - just so that the tip is perfectly smooth, but still has enough material thickness.

Polishing the tips

The thickening of the needle tip (caused by sharpening) must now be removed by polishing - just so that the tip is perfectly smooth, but still has enough material thickness.

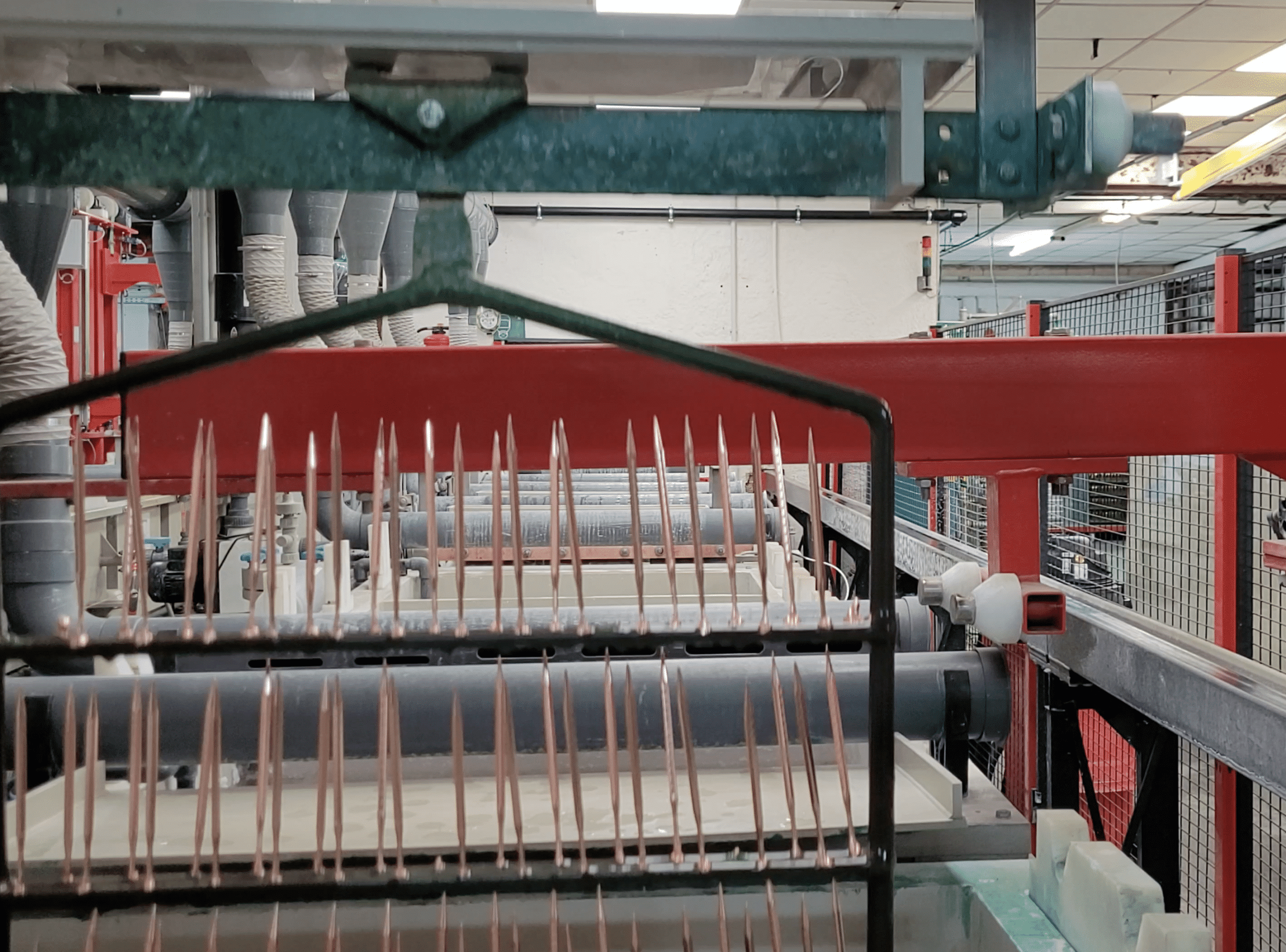

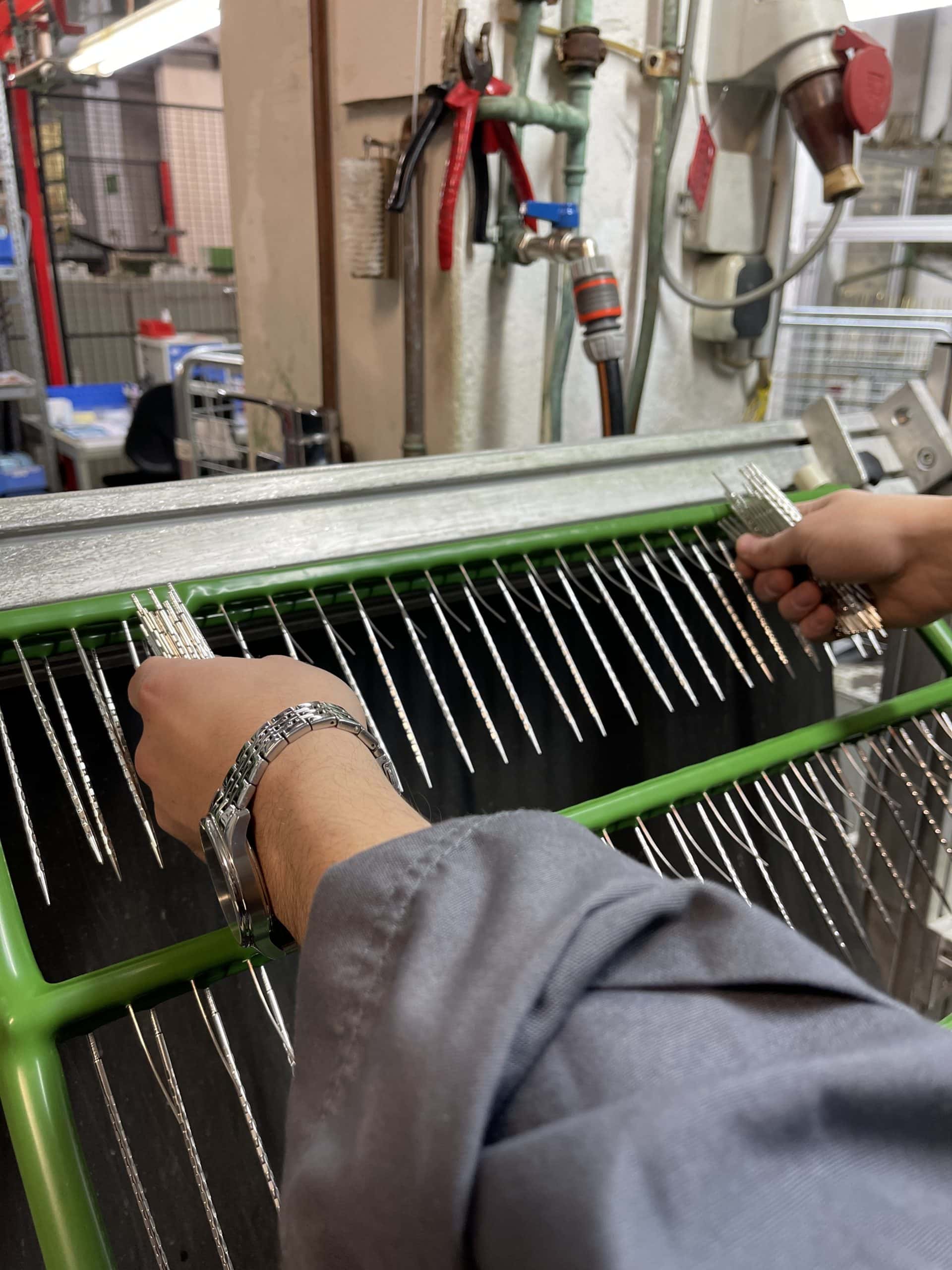

Precise pre-treatment of the pipes with a tolerance of 1/100 mm

In several steps, the brass tips are now precisely processed - polished, sorted and then placed on racks by hand for galvanic surface finishing.

Precise pre-treatment of the pipes with a tolerance of 1/100 mm

In several steps, the brass tips are now precisely processed - polished, sorted and then placed on racks by hand for galvanic surface finishing.

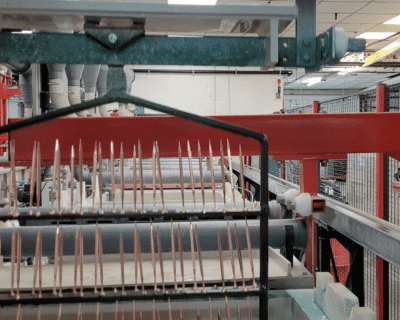

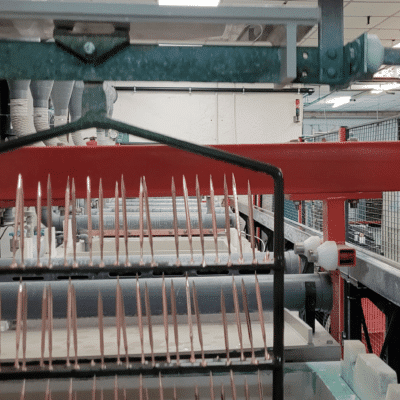

Finishing with white bronze through 25 baths

Now the racks with the needle tips go through 25 galvanic baths for the perfect white bronze surface.

Our system was newly built in 2016 to be water, energy and resource efficient.

Finishing with white bronze through 25 baths

Now the racks with the needle tips go through 25 galvanic baths for the perfect white bronze surface.

Our system was newly built in 2016 to be water, energy and resource efficient.

Post-treatment electroplating

After the white bronze surface finishing, the tips have to be taken off the racks again by hand and sorted into boxes for further processing.

Post-treatment electroplating

After the white bronze surface finishing, the tips have to be taken off the racks again by hand and sorted into boxes for further processing.

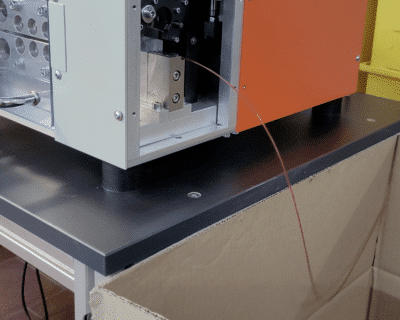

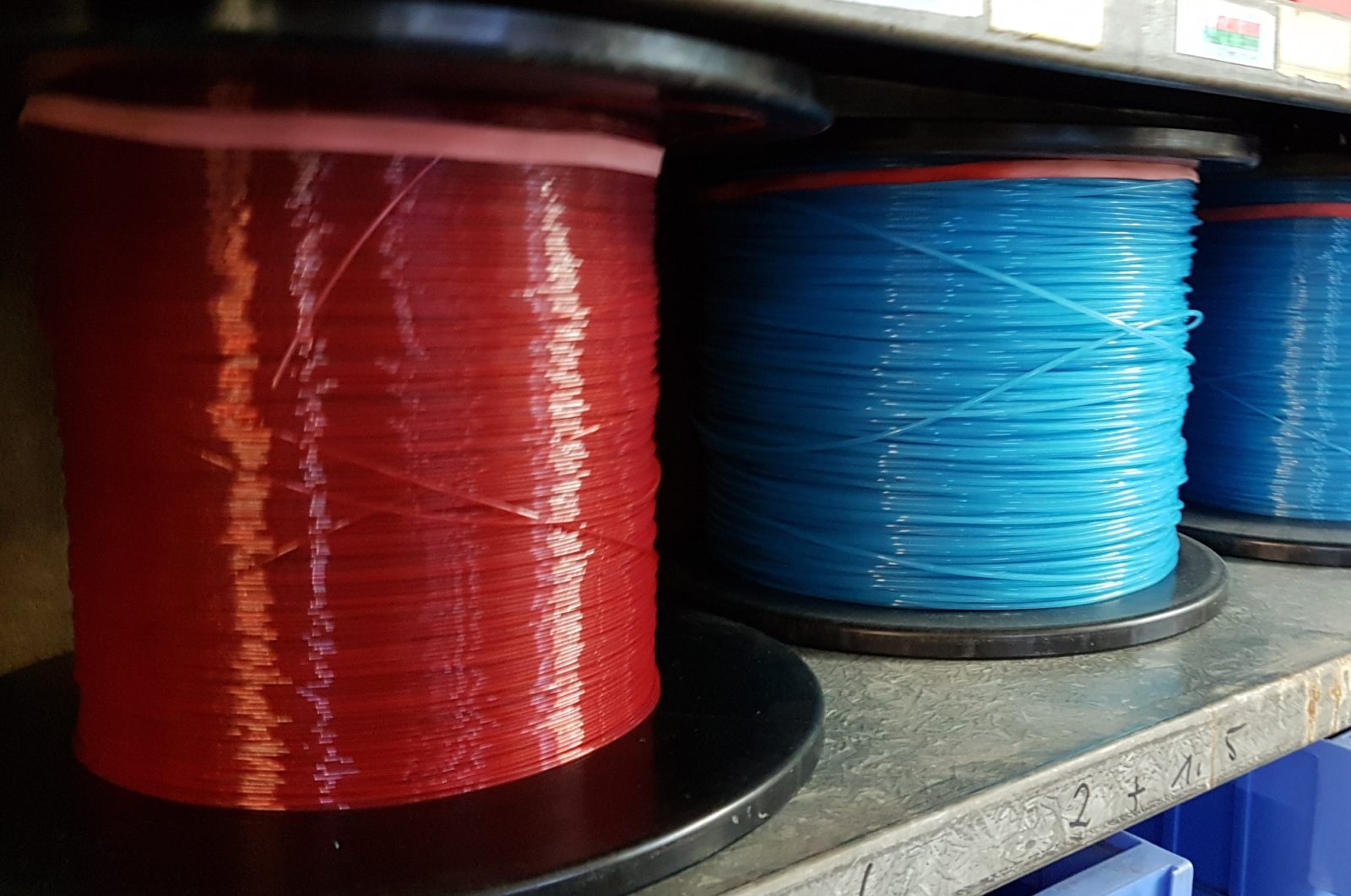

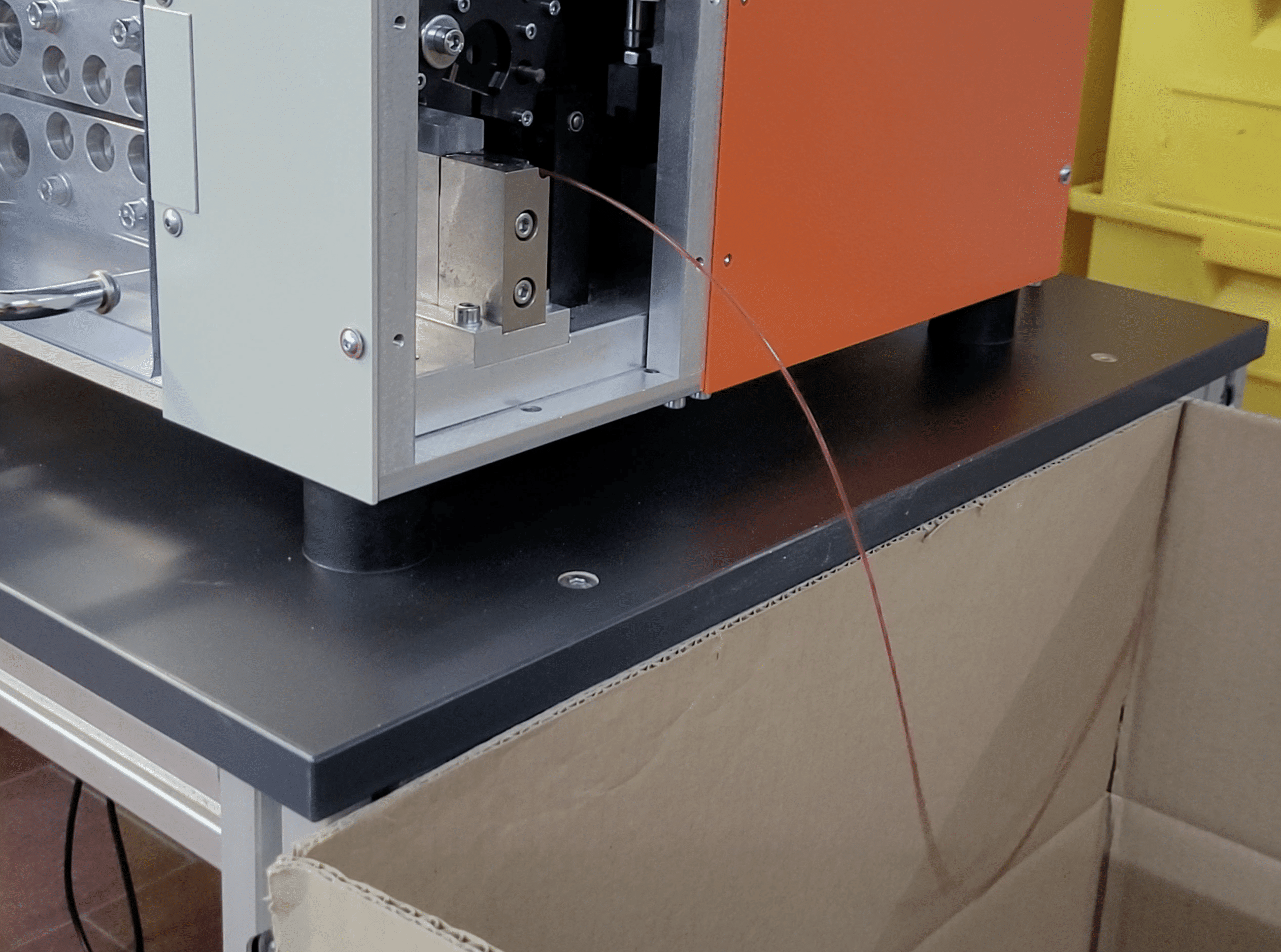

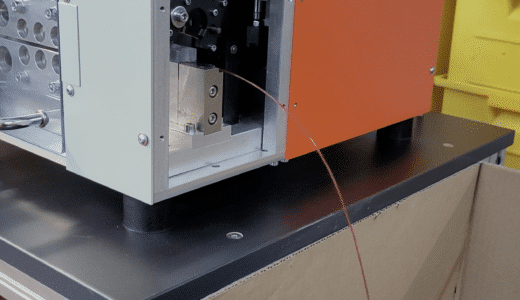

addi print and cut cords

Now the other components of the needles are prepared - the cords are cut into the right lengths for circular knitting needles, addiClick or also addiCraSyTrios. The red ropes are for our lace needles, the golden ones for our basic lace and wooden needles and then there are special colours like pink for our addiUnicorn series, blue (exclusively for our US partner Skacel) as well as black.

addi print and cut cords

Now the other components of the needles are prepared - the cords are cut into the right lengths for circular knitting needles, addiClick or also addiCraSyTrios. The red ropes are for our lace needles, the golden ones for our basic lace and wooden needles and then there are special colours like pink for our addiUnicorn series, blue (exclusively for our US partner Skacel) as well as black.

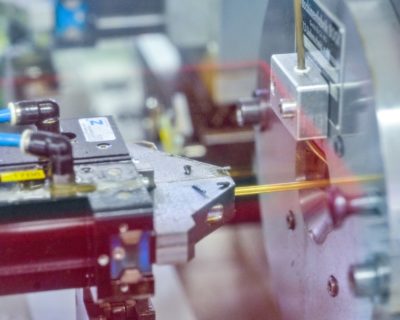

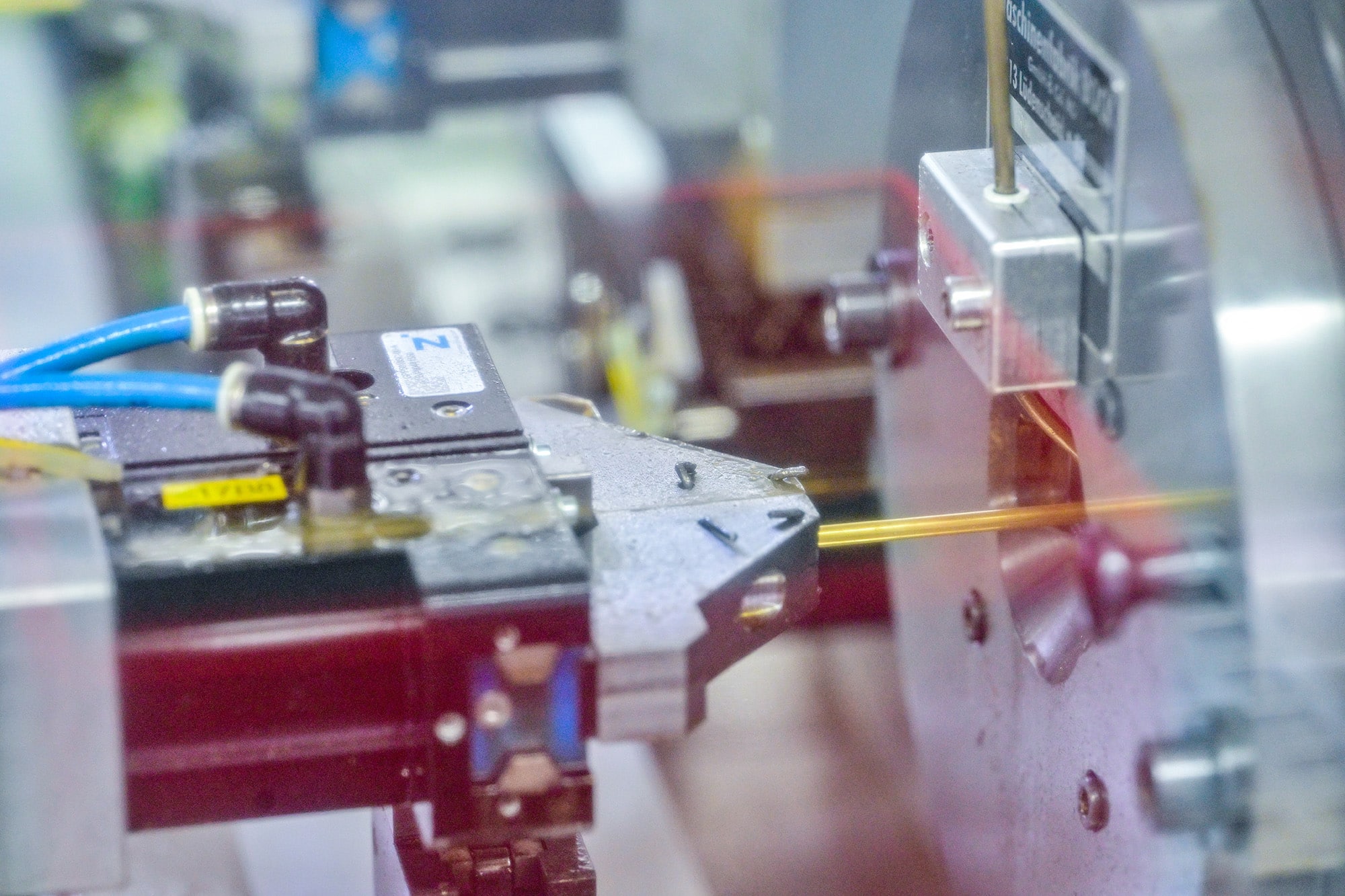

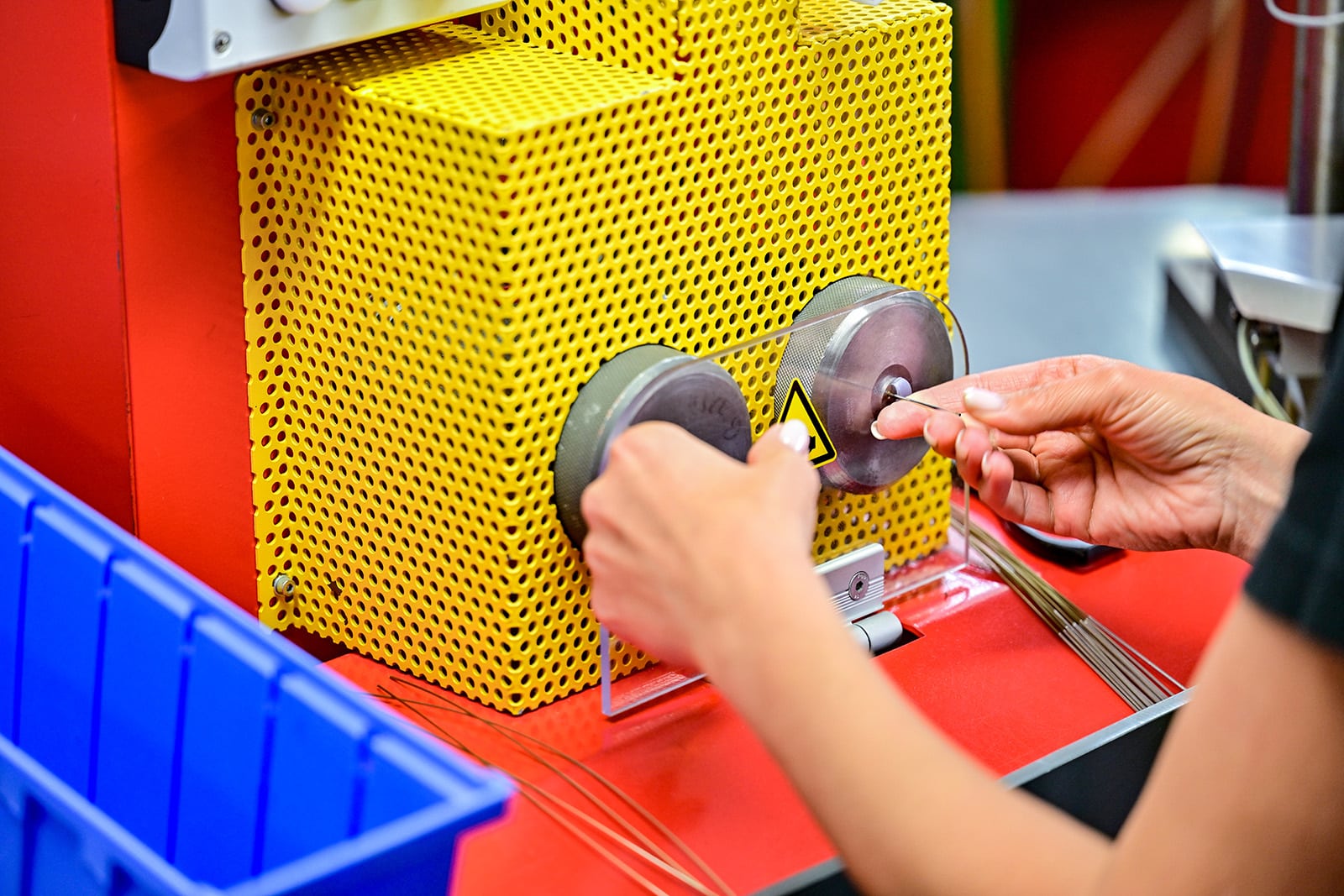

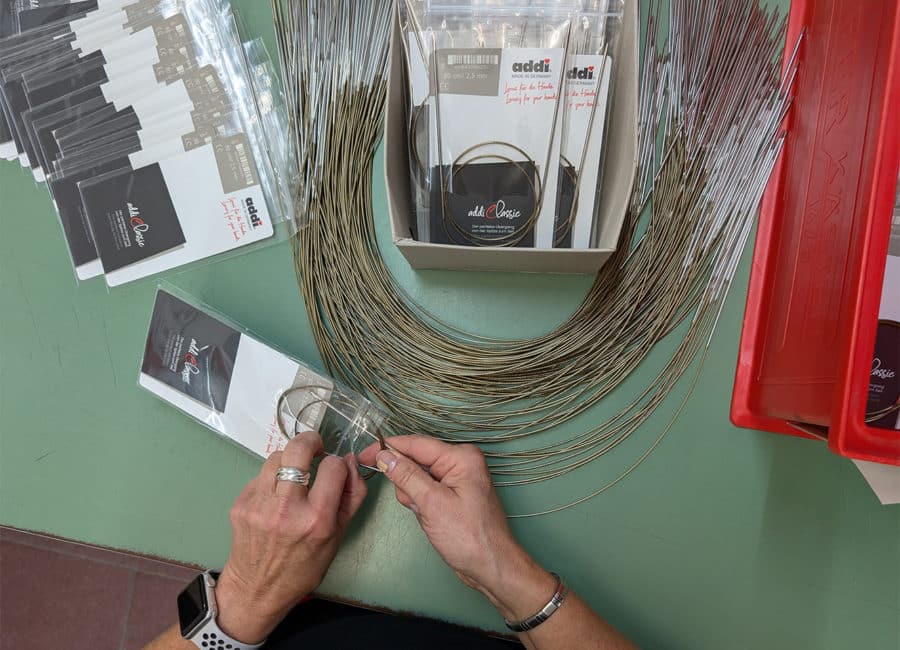

Connect (marry) tips and cord

Eine besondere Aufgabe ist das „verheiraten“ der Nadeln. Hier wird nicht nur das Seil in den Nadelspitzen befestigt, sondern auch der besonders glatte Übergang von der Nadel zum Seil geschaffen. Eine Aufgabe für die viel Erfahrung und Feingefühl benötigt wird.

Connect (marry) tips and cord

Eine besondere Aufgabe ist das „verheiraten“ der Nadeln. Hier wird nicht nur das Seil in den Nadelspitzen befestigt, sondern auch der besonders glatte Übergang von der Nadel zum Seil geschaffen. Eine Aufgabe für die viel Erfahrung und Feingefühl benötigt wird.

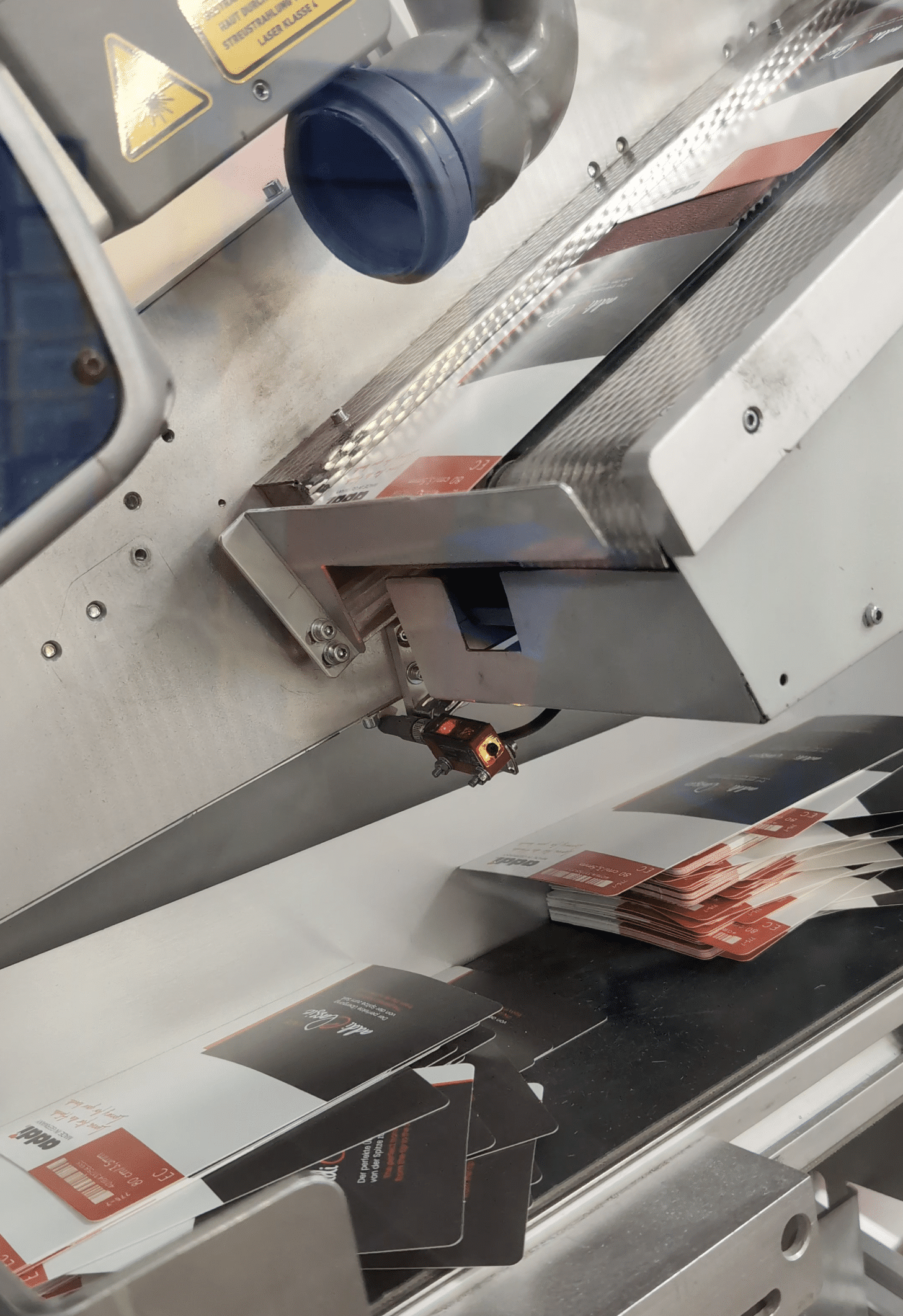

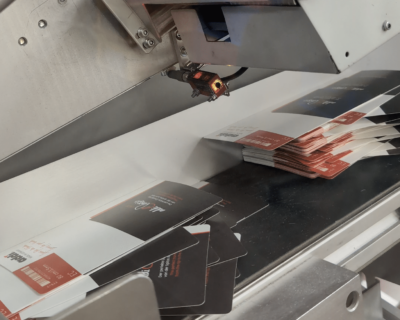

Print slipcase

Each needle series has its own slipcase and each slipcase is lasered on the top left of the colour area to show the respective gauge and length information before the needle and slipcase are then packed by hand into bags.

Some customers sell our needles with their own pushers, such as our US partner Skacel, the Lang company or Sandnes and Rauma.

Print slipcase

Each needle series has its own slipcase and each slipcase is lasered on the top left of the colour area to show the respective gauge and length information before the needle and slipcase are then packed by hand into bags.

Some customers sell our needles with their own pushers, such as our US partner Skacel, the Lang company or Sandnes and Rauma.

Packing needles

The needles are then packed by hand and bundled into groups in boxes. These are then shipped directly to our partners (wholesalers and dealers) all over the world.

Packing needles

The needles are then packed by hand and bundled into groups in boxes. These are then shipped directly to our partners (wholesalers and dealers) all over the world.

Send to addiFans

The circular knitting needle is now on its way to the wholesalers and the shops.

Send to addiFans

The circular knitting needle is now on its way to the wholesalers and the shops.