The question of packaging

Plastic is bad, paper is good, glass is an ecologically sensible packaging and unpackaged is the best anyway? These are the questions that we at addi have been dealing with for many, many years. Because the reality is much more complex.

What criteria must addi packaging meet?

At addi, there is a lot to consider when it comes to packaging. We have a lot of diversity within our products, which means the packaging has to be flexible. It has to be usable for the different sizes of products and series. Some of our customers carry private labels, so the packaging must be customizable, even in small quantities.

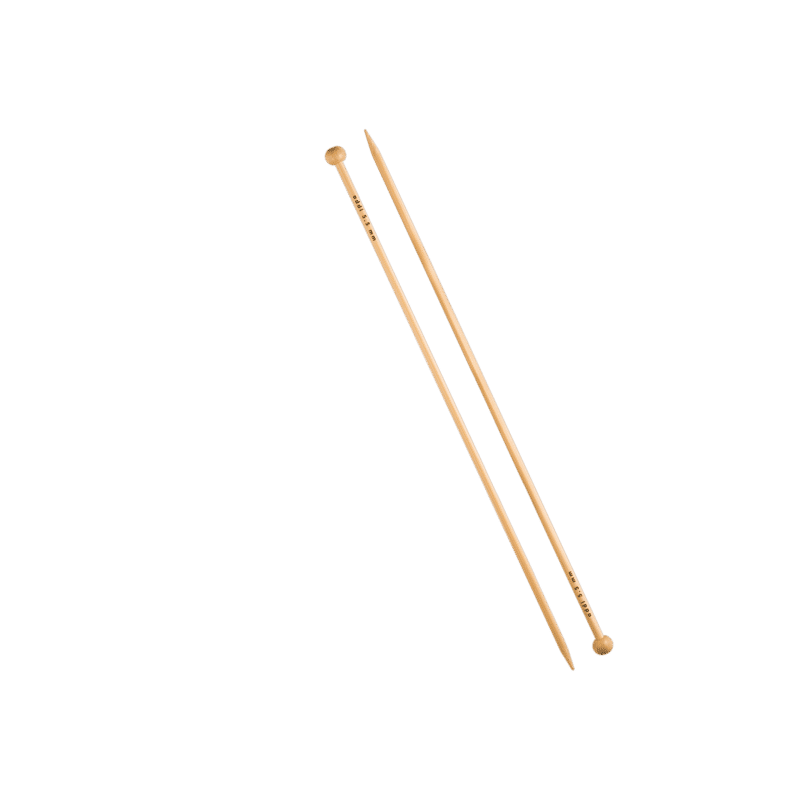

For retail stores, the packaging should also have Euro perforation and it must not be too bulky, i.e. flat and as narrow as possible. This is because space is limited in retail stores.

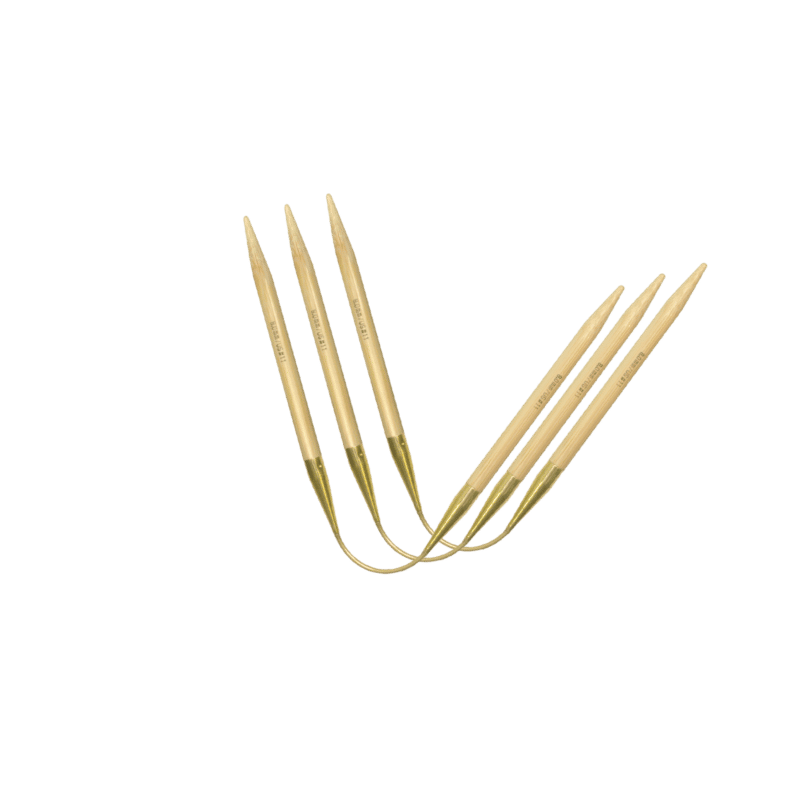

Needles have pointed tips – especially the lace needles – so the packaging must be puncture-resistant. It is also important to us that the individual needle is visible, the product is packable and the packaging is reusable, and, and, and…one could list much more.

What criteria must addi packaging meet?

At addi, there is a lot to consider when it comes to packaging. We have a lot of diversity within our products, which means the packaging has to be flexible. It has to be usable for the different sizes of products and series. Some of our customers carry private labels, so the packaging must be customizable, even in small quantities.

For retail stores, the packaging should also have Euro perforation and it must not be too bulky, i.e. flat and as narrow as possible. This is because space is limited in retail stores.

Needles have pointed tips – especially the lace needles – so the packaging must be puncture-resistant. It is also important to us that the individual needle is visible, the product is packable and the packaging is reusable, and, and, and…one could list much more.

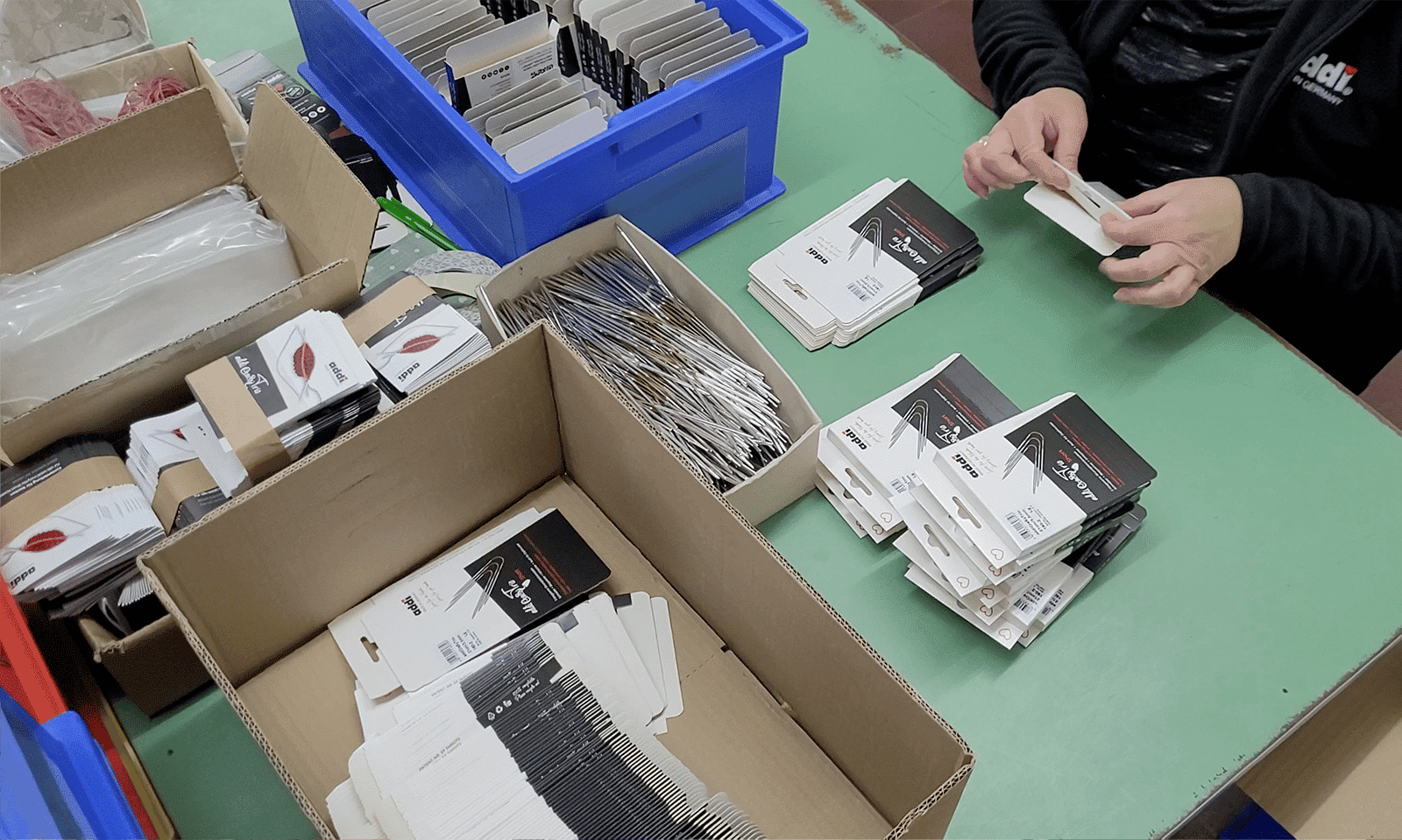

Production in Germany

There is also the fact that we are in the low price segment with production in Germany, so the packaging must be reasonably priced. In addition, every single one of our products is packed by hand. With 40,000 needles produced per day, packing must not take a disproportionate amount of time.

Production in Germany

There is also the fact that we are in the low price segment with production in Germany, so the packaging must be reasonably priced. In addition, every single one of our products is packed by hand. With 40,000 needles produced per day, packing must not take a disproportionate amount of time.

The polybag with slipcase

Yes, addi uses poly bags with a paper slipcase. At least for the circular knitting needles. Why did we choose plastic packaging for the circular knitting needles?

When you think about all these aspects, it quickly becomes clear that there is hardly any packaging that meets all the criteria. The product is visible and can be evaluated at the time of purchase. The packaging can be reused and it takes up little space at the point of sale.

In addition, the pure materials plastic and cardboard can be separated very easily to 100%.

The polybag with slipcase

Yes, addi uses poly bags with a paper slipcase. At least for the circular knitting needles. Why did we choose plastic packaging for the circular knitting needles?

When you think about all these aspects, it quickly becomes clear that there is hardly any packaging that meets all the criteria. The product is visible and can be evaluated at the time of purchase. The packaging can be reused and it takes up little space at the point of sale.

In addition, the pure materials plastic and cardboard can be separated very easily to 100%.

Here at addi we have come to the conclusion that the polybag is a good alternative to cardboard packaging. Because by no means is paper packaging always really the best for the climate and the environment.

As analyses reveal, plastic film, for example, can sometimes be better than paper or cardboard. This is because although paper and cardboard are produced from renewable wood, their manufacture involves the use of many chemicals that pollute wastewater. In addition, the energy used ensures CO2 emissions.

Aussagen wie „Papier besteht aus nachwachsendem Holz, Kunststoff dagegen aus endlichem Öl“ sind leicht gesagt und auch erstmal nachvollziehbar, doch leider muss man unterscheiden: Does the wood come from sustainable forestry? Is the plastic used recyclable? Can the end product be reused? How much energy does the production process consume?

The fact is that paper packaging is up to twice as heavy as plastic packaging with the same tear strength, offers only limited product protection and, above all, as already mentioned, requires significantly more energy, water and chemicals for production.

Here at addi we have come to the conclusion that the polybag is a good alternative to cardboard packaging. Because by no means is paper packaging always really the best for the climate and the environment.

As analyses reveal, plastic film, for example, can sometimes be better than paper or cardboard. This is because although paper and cardboard are produced from renewable wood, their manufacture involves the use of many chemicals that pollute wastewater. In addition, the energy used ensures CO2 emissions.

Aussagen wie „Papier besteht aus nachwachsendem Holz, Kunststoff dagegen aus endlichem Öl“ sind leicht gesagt und auch erstmal nachvollziehbar, doch leider muss man unterscheiden: Does the wood come from sustainable forestry? Is the plastic used recyclable? Can the end product be reused? How much energy does the production process consume?

The fact is that paper packaging is up to twice as heavy as plastic packaging with the same tear strength, offers only limited product protection and, above all, as already mentioned, requires significantly more energy, water and chemicals for production.

More carton

All other packaging is already made of cardboard or is currently being converted to cardboard packaging. The most important reason for this is that the addi tubular packaging, for example, no longer meets our quality requirements.

This changeover affects, for example, DPNs and crochet hooks. Gradually, our stocks of the packaging will be used up and then the new packaging will be introduced.

More carton

All other packaging is already made of cardboard or is currently being converted to cardboard packaging. The most important reason for this is that the addi tubular packaging, for example, no longer meets our quality requirements.

This changeover affects, for example, DPNs and crochet hooks. Gradually, our stocks of the packaging will be used up and then the new packaging will be introduced.

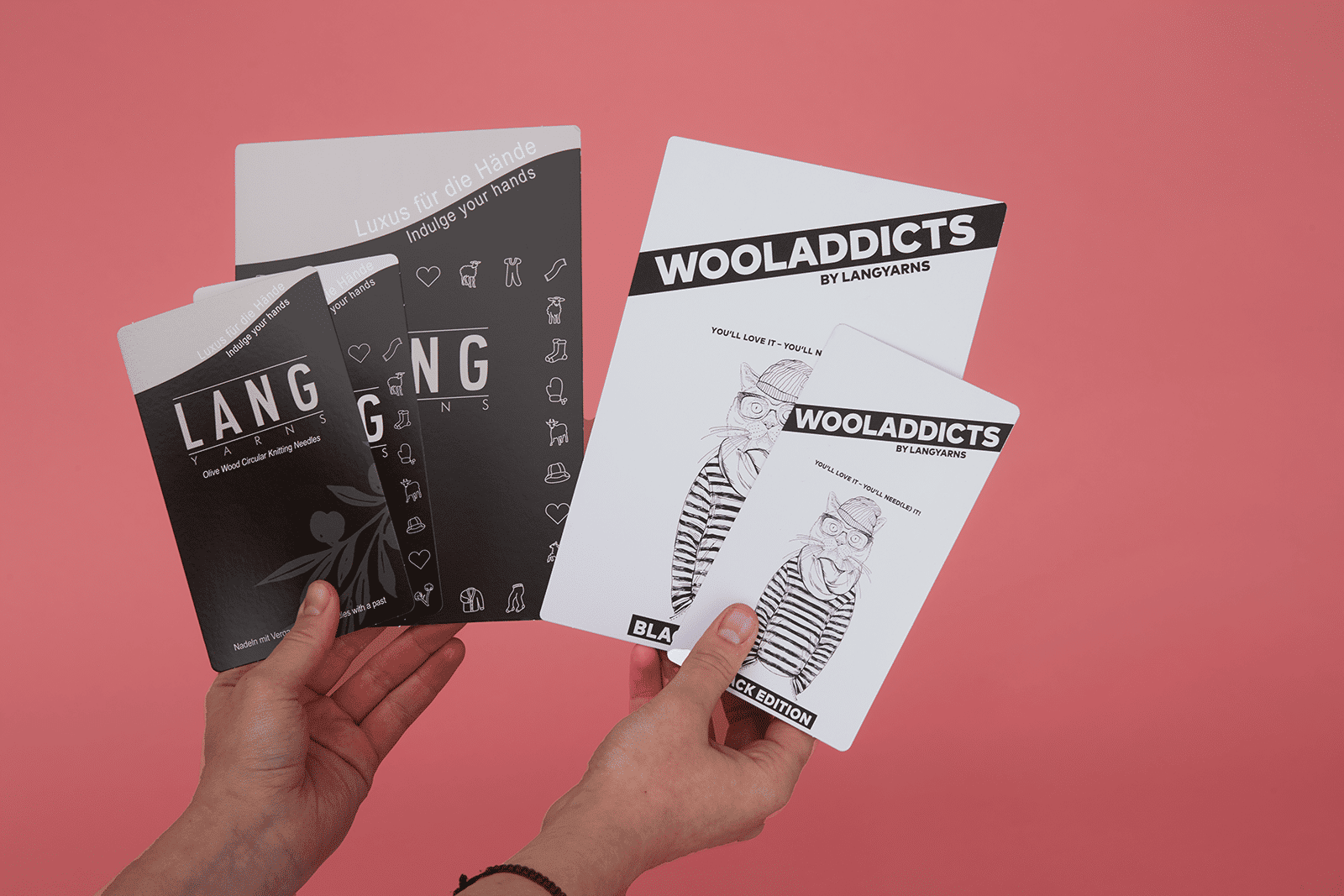

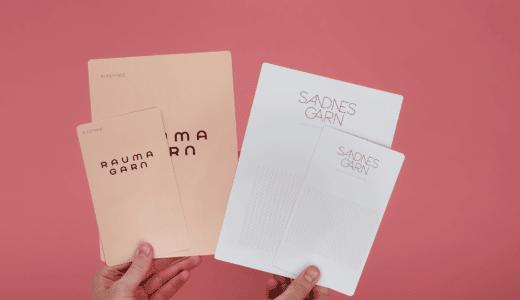

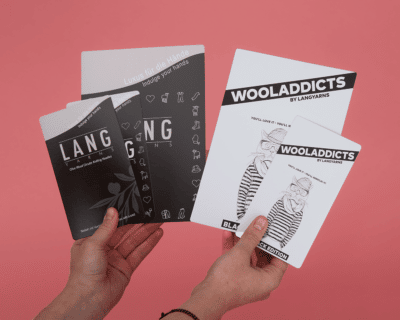

Conversion of packaging and design

In step with the introduction of new packaging, our new, brighter addi design will also be introduced, which we introduced with our new website in 2022.

Gradually, it will be implemented for all packaging. We are relying on less use of printing inks, in that the basic color of the packaging – white – will replace the previously dominant black.

In addition, our product series will be differentiated by color, which will make them easier to distinguish. We are focusing on more linking of digital information and clear communication of our brand – made in Germany.

Thus, there will be a transition period in which both old (black) and new (white) packaging will be in circulation.

Conversion of packaging and design

In step with the introduction of new packaging, our new, brighter addi design will also be introduced, which we introduced with our new website in 2022.

Gradually, it will be implemented for all packaging. We are relying on less use of printing inks, in that the basic color of the packaging – white – will replace the previously dominant black.

In addition, our product series will be differentiated by color, which will make them easier to distinguish. We are focusing on more linking of digital information and clear communication of our brand – made in Germany.

Thus, there will be a transition period in which both old (black) and new (white) packaging will be in circulation.

Our conclusion

The subject of packaging is very complex. There is a lot more to consider and assess than trusting a number of blanket statements. It is a challenge to find the ecologically perfect packaging that at the same time meets the demands of packaging for the respective product.

addi stands for transparency and openness. But also for sustainability and quality. Finding the balance between the latter two is our key to success.

Our conclusion

The subject of packaging is very complex. There is a lot more to consider and assess than trusting a number of blanket statements. It is a challenge to find the ecologically perfect packaging that at the same time meets the demands of packaging for the respective product.

addi stands for transparency and openness. But also for sustainability and quality. Finding the balance between the latter two is our key to success.